Forged shackles is a common manufacturing method that forms the desired shackle shape by heating a metal material to a malleable state and then applying pressure and impact. The following is the basic manufacturing process for forging shackles:

1. Material preparation:

Select suitable metal materials, such as steel, stainless steel, alloy steel, etc. The material should have the required strength, toughness and corrosion resistance.

2. Heating:

The heating of a metal material to the appropriate temperature of its plastic region. Heating can be done using a high temperature furnace or other heating equipment.

3. Forging:

Pressure and impact are applied to a heated metal material to transform it into the desired shackle shape. The forging process can be used in different ways, such as impact forging, free forging or pressure forging. It is usually operated with a forging hammer, press or other specialized forging equipment.

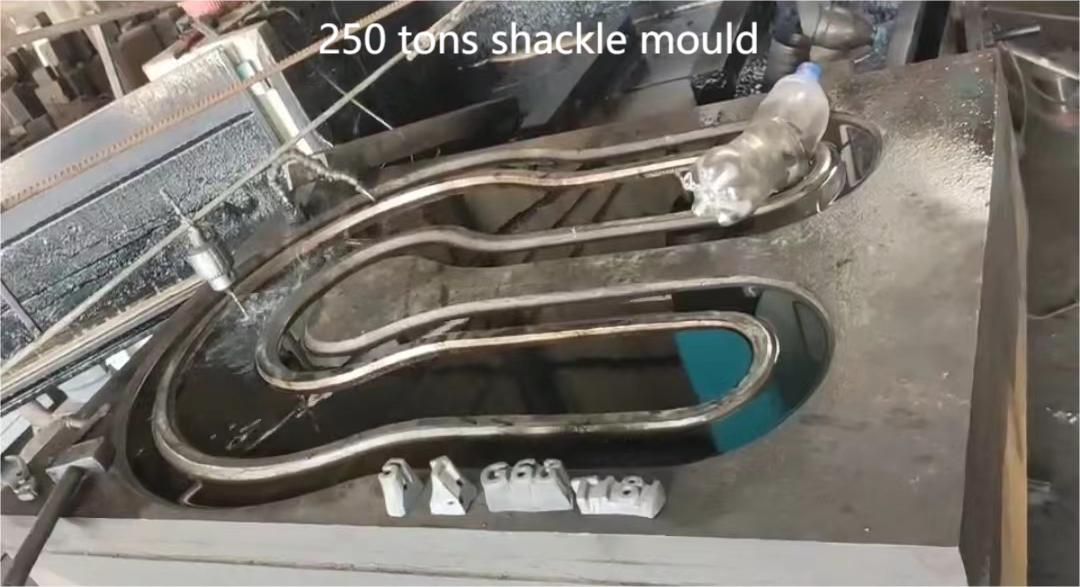

It is worth mentioning that even large size shackles, such as 250 tons, 150tons, 85tons, Qingdao Sipower also have corresponding molds.

4. Shaping and finishing:

After initial forging, shackles may require further shaping and finishing. This may include trimming edges, sanding surfaces, drilling or cutting.

5. Heat treatment:

Some shackles may require heat treatment to improve their mechanical properties. Common heat treatment methods include quenching, tempering and normalizing, selected according to material and design requirements.

6. Surface treatment:

In order to enhance the corrosion resistance and appearance of the shackle, surface treatment can be performed. This may include galvanizing, chrome plating, electroplating or hot dip galvanizing.

7. Inspection and quality control:

The necessary inspection and quality control are carried out during the manufacturing process to ensure that the shackles comply with design requirements and standards. This may include appearance checks, dimensional measurements, strength tests, and destructive tests.

It should be noted that the manufacturing method of forged shackles can be adjusted according to the specific design requirements and material selection. In the actual manufacturing process, the relevant process specifications and standards should be followed to ensure that the quality and performance of the shackle meet the requirements.